» Notizia & FAQ » How to inspect the aircraft turbines with an industrial videoscope?

Case Background:

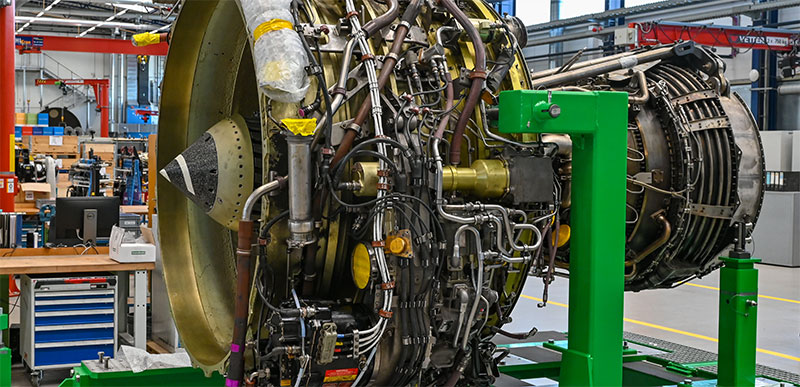

In the aviation industry, aircraft turbine is a key power unit, and the stability and reliability of its performance is crucial to the safety of aviation operation, so it needs to be safely inspected from time to time, and industrial endoscope is one of the instruments widely used in the safety inspection of aircraft turbine.

hendoss videoscope for aircraft turbines inspection

Case Description:

At an aviation maintenance workshop, a jet airliner turbine engine was experiencing problems with rattling and vibration. In order to determine the cause of the problem and make a prompt repair, the engineers decided to inspect the turbine engine using an industrial endoscope.

Step 1: Preparation

The engineers first selected high-resolution industrial endoscopic equipment suitable for aviation maintenance and checked the condition and performance of the equipment to ensure that it worked properly. At the same time, the engineers also prepared the necessary protective equipment, such as helmets, protective glasses and earplugs, to ensure the safety of the inspection process.

Step 2: Turbine Disassembly

The turbine engine is disassembled and broken down into different modules for better endoscopic inspection. Engineers perform a step-by-step disassembly according to the engine’s structure and maintenance manuals, breaking it down into major modules such as the compressor, combustion chamber and turbine.

Step 3: Borescope Inspection

The engineer inserts the borescope probe into the pre-designated probe hole and slowly enters the turbine interior for inspection by operating the probe, and transmits the captured image information to the screen through the optical system so that the engineer can observe the detailed state of the turbine interior.

During the inspection process, the engineer scrutinizes the surface of the turbine blades to check for problems such as cracks, wear or deformation. The industrial endoscope’s high-resolution images capture minute defects and anomalies, helping engineers determine the health of the turbine. If a problem is found, the engineer will document it and share it with the team after the inspection is complete.

Step 4: Reporting and Repair

Based on the results of the endoscopic inspection, the engineer writes an inspection report detailing the problems with the turbine and generates a repair report, which is submitted to the repair team, who will repair and replace the turbine accordingly.

hendoss videoscope for aircraft turbines inspection

Conclusion:

Through the application of industrial endoscopy, the engineers successfully detected the problems with the turbine of the airplane and provided repair recommendations accordingly. This effectively solved the turbine engine rattling and vibration problems and ensured the safety and reliability of aviation operations. The high-resolution images and real-time view of the industrial endoscope provide a strong guarantee for aircraft maintenance and troubleshooting.